Through our experience in training for LeanSigma process improvement, we've helped small and medium businesses to internalize the proven techniques to create and maintain a dramatic improvement in their business processes.

The difference:

- All training LeanSigma are action-oriented and distilled from practical experience, rooted in the fundamentals of the Toyota Production System.

- Our trainers are Tangolf Inc. senior consultants providing more than 25 weeks per year of teaching and application of tools and processes that will be thought.

- Our instructors are recognized as experts in their fields.

- The ratings of appreciation given by the trainees after their learning experience are among the highest.

Certification

Lean certification - Kaizen Facilitator

Lean certification - Kaizen Facilitator

Develop your own leadership in Lean and strengthen internal capacities to support your Lean deployment of internal, and accelerate results. For your employees in this workshop, the first day of a Kaizen event is probably a first foray into Lean and Kaizen concepts, as well as the objectives and motivations of your business faced to this training program.

Develop your own leadership in Lean and strengthen internal capacities to support your Lean deployment of internal, and accelerate results. For your employees in this workshop, the first day of a Kaizen event is probably a first foray into Lean and Kaizen concepts, as well as the objectives and motivations of your business faced to this training program.

As a Kaizen Promotion Officer (KPO), you need to do better than a simple presentation. To achieve your goal, you must exercise pedagogy, persuasion and motivation for each Kaizen team and make them aware of the potential of Lean adventure.

You must achieve to produce a positive winning impression to ensure your success and this is essential to introduce cultural change. Our consultants have taught many times that first day of a Kaizen event and they will make you enjoy their experience through interactive simulations, role plays and staging.

Who Should Attend?

- Instructors or Lean Kaizen Promotion Officer (KPO)

- Continuous improvement specialists

Testimonials :

Before participating in this seminar, our knowledge of Lean and Kaizen were very limited. In return, we were completely excited and were anxious to return to apply what we saw, did and learned during the week.

Lean Six Sigma Champion certification

Lean Six Sigma Champion certification

The commitment to the Six Sigma spirit has become mandatory for companies that have identified it as the most effective way to meet the requirements of customers and shareholders. This one day course aims to provide leaders with a detailed vision of Six Sigma, of its implementation and the benefits that the company can draw. The course, also available as private, can be used to arouse the interest of management to the professional courses of Green Belt / Black Belt or cause of the launch and support of a Six Sigma project.

The commitment to the Six Sigma spirit has become mandatory for companies that have identified it as the most effective way to meet the requirements of customers and shareholders. This one day course aims to provide leaders with a detailed vision of Six Sigma, of its implementation and the benefits that the company can draw. The course, also available as private, can be used to arouse the interest of management to the professional courses of Green Belt / Black Belt or cause of the launch and support of a Six Sigma project.

LeanSigma Champions are crucial elements of your team to implement Lean as they serve to promote and support the success of your Lean initiative, and this by:

- Ensuring that your LeanSigma projects are in line with your industrial / commercial targets;

- Selecting appropriate teams to implement;

- By monitoring progress and preparing reports;

- Removing obstacles to success.

During this certification that may be taken place in a Tangolf Inc client’s factory, training is delivered as a combination of lectures, presentations and interactive exercises.

Who Should Attend?

- Do you understand what the Six Sigma approach can bring to the organization of your business?

- Need to update your knowledge on the strategy of improvement made by the technical Six Sigma?

- Do you know how to implement Six Sigma projects to identify your priorities and be at the leading edge of progress?

If you answered YES to any of these questions, then this training is for you.

Testimonials :

I am now able to better evaluate the application of LeanSigma. I enjoyed the contact with other participants. The simulations are practical and very visual; therefore, they have a big impact.

Personalized training

Tangolf Inc. works with several clients that require a personalized training program. We have the ability to provide this training. We want to ensure that your employees are able to implement the training they receive. The other focus for our personalized training program is the Return On Investment (ROI) that is often neglected in training programs.

Looking for daily continuous improvement

Looking for daily continuous improvement

A five-day seminar is taught in this workshop at a highest order Lean enterprise, providing essential training for managers. The first line managers, production managers, managers of group support and production teams can achieve and sustain effective and continuous improvement every day. Besides training on the use of visual management tools, eliminating waste and improving daily, the workshop provides an important interaction with senior staff to develop action plans.

A five-day seminar is taught in this workshop at a highest order Lean enterprise, providing essential training for managers. The first line managers, production managers, managers of group support and production teams can achieve and sustain effective and continuous improvement every day. Besides training on the use of visual management tools, eliminating waste and improving daily, the workshop provides an important interaction with senior staff to develop action plans.

At the end of this seminar, participants will be able to:

- Implement and maintain operational standards in the work area.

- Monitor and maintain the visual quality metrics to meet or exceed daily production goals.

Who Should Attend?

- Responsible for front line team leaders and mediators line.

- Responsible for production, process and support groups.

- Responsible for continuous improvement or Kaizen Promotion.

- Plant managers, division and department.

Testimonials:

The key word is speed. Our transformation LeanSigma greatly motivated our staff and helped us understand what true teamwork. Within a year, we generated 4x the rate of return on investment through increased production and efficiency

Optimizing administrative processes

Optimizing administrative processes

This training allows us to understand and deploy a structured methodology designed to eliminate the causes of waste in administrative services. Its goal is to optimize the efficiency of administrative activities of your business by reducing processing times and operating costs while improving the reliability and the quality of information. It helps develop a new vision of processes organized around activities with high added value in a dynamic of continuous improvement.

This training allows us to understand and deploy a structured methodology designed to eliminate the causes of waste in administrative services. Its goal is to optimize the efficiency of administrative activities of your business by reducing processing times and operating costs while improving the reliability and the quality of information. It helps develop a new vision of processes organized around activities with high added value in a dynamic of continuous improvement.

In addition to the technical "Lean Manufacturing", this course offers the opportunity to involve the indirect activities of your business in a global "Lean Enterprise" optimization approach.

Who Should Attend?

- For CEOs.

- For directors and managers of industries and administrative, financial, buying departments, and human resources.

- For managers, company officials involved in a Lean project.

Testimonials:

An enjoyable seminar that I leave feeling quite capable of achieving positive improvements in my organization.

Conferences and seminars

Designed to encourage benchmarking, networking and sharing, our conferences and seminars include a combination of case presentations, panel discussions, roundtables, working sessions to develop solutions to current issues. Throughout the year, Tangolf Inc. gives presentations at conferences and seminars.

See our events calendar to learn more about other opportunities to hear experts Tangolf Inc. and share their ideas about Lean is an antidote to driving and maintaining profitable growth.

For a successful Lean process race

For a successful Lean process race

For many of you, the first contact with Kaizen stands during a Kaizen event on the ground like a plant, during which you will find the typical results that Kaizen teams get in a few days only: significant reduction of manufacturing lead times, fewer defective stocks, all with a considerable increase in productivity.

Now, when your employees return to their business, full of enthusiasm and determined to be reproducing the same results, their task is far from easy and this, mainly because of the lack of structure. Any company getting quality results through Kaizen is, indeed, with a Kaizen Promotion Office (KPO), ie, with an internal team responsible to motivate teams, teach and implement Lean Industrial production.

In this interactive seminar, the upgrading of skills is powered by a combination of lectures, simulations and exercises. Now, the uncertainty will give way to a clear roadmap of your adventure Lean.

Who Should Attend?

- For CEOs.

- For managers and plant personnel.

- For the management teams of Operations.

- For leaders and team members to promote continuous improvement, Lean and KPO.

Testimonials :

Very valuable. This will help to introduce and promote the Voice of the Customer, the House of Quality, Research ideas (Brainstorming, Kaizen), the use of scorecards, the curve analysis of the risk / value and other program activities of product development.

LeanSigma for processes industry

LeanSigma for processes industry

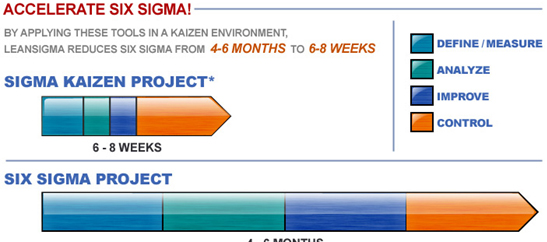

This two-day seminar offers an overview of an industrial strategy proven to dramatically improve your performance with LeanSigma in a fraction of the time required for traditional Six Sigma tools used alone; this seminar is at the level of the process industries direction.

We can also arrange this seminar for your company on site for a group not exceeding 20 employees.

Launched for the first time by Tangolf Inc., the LeanSigma approach is currently the fastest and most effective for the improvement of industrial activity. By combining the rapid elimination of waste and the reduction of delays of Lean with the concentration of Six Sigma on the improvement of quality and performance, LeanSigma offers to the industries of process an unprecedented innovative boost in a fraction of the time needed Six Sigma tools alone.

If you strive to make innovative improvements, are certain of the approach or trust the traditional Six Sigma tools to change things, we invite you to experience the speed and spectacular impact of LeanSigma.

LeanSigma is used today to generate competitive advantages in the revolutionary process industries worldwide.

Who Should Attend?

- Management Team comprising the Director General, President, COO and CFO.

- Marketing Managers, Operations, Engineering, Continuous Improvement, Quality, Materials and Human Resources.

Testimonials :

The first product we developed with this process was on the market in one third of our normal time. Its concept is unlike any other comparable product with benefits that our customers are truly satisfied. Our main competitor is already asking us a licence of that new product.

KPO / LeanSigma exchange

KPO / LeanSigma exchange

A unique gathering of 2 days to collect Lean experienced leaders from a wide range of companies - industrial or service - to share their adventure Lean, lessons learned and best practices.

A unique gathering of 2 days to collect Lean experienced leaders from a wide range of companies - industrial or service - to share their adventure Lean, lessons learned and best practices.

This annual event is hosted by a Tangolf Inc. client who has largely proven in implementing Lean. In areas of continuous improvement, leaders and change agents are aware of the existence of a flow of concrete experiences difficult to harness and put into practice. The global network of Lean specialists gathered at meetings KPO / LeanSigma of Tangolf Inc. recognizes the importance of this wealth of knowledge, which is why he considers this as the best conference on Lean practices possible.

Who Should Attend?

- For all those interested in learning the latest strategies for continuous improvement to the implementation of industrial production Lean Services Lean techniques and Six Sigma throughout the value chain.

Testimonials :

This is an excellent facelift - and a great opportunity to refocus and share new experiences and innovations.